Features

- Material selection: PC, PET, PMMA, and all kind of metal and plastic

- Various surface treatments: simulated metal, wood, leather, carbon fiber effects

- Diverse tactile feedback: partial or full texture

- Meet abrasion resistance requirements: passed pencil hardness and RCA abrasion tests

- Tailor pattern design: holographic, mineral grain, concentric circles, spiral, etc.

Benefits

- One-stop shopping: enhance procurement efficiency and simplify NPD processes for shorter time to market

- Multi-color effect: enable to achieve multi-color effect on affixed plastic surface

- Create product differentiation: promote product sales, generate revenue and create brand identity

- Cost advantage: lower cost than spray painting and anodizing treatment, lower MOQ requirements

- Eco-friendly: eliminate usage of spray painting and acid solution, higher yield rate, less waste, less energy consumption

- Lightweight products: combine printing and surface treatments for a metallic effect while having the benefits of cost efficiency, enhanced appearance, lighter weight, and thinner dimensions.

- Application: Brand Logo, Decorative plate/back cover of mobile phone, Electric conductive/veined pattern material for panel of household appliance

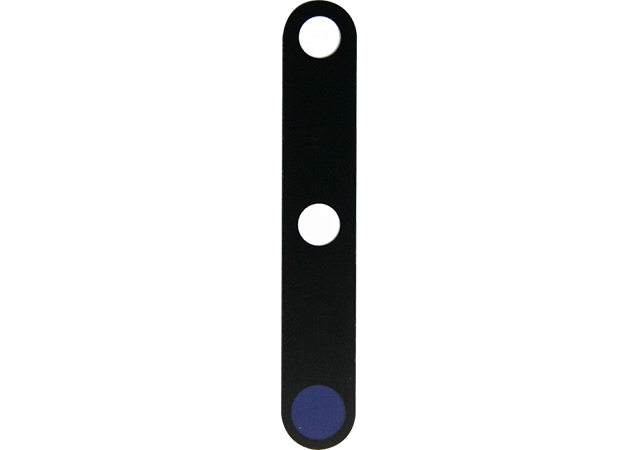

Success Stories: Acer 3D Active Three-Hole Glasses

Requirements

- The product contained Intel 3D imaging system. End users could operate computer system through the infrared sensor.

- Intel 3D imaging system needed high transmittance 3D interactive three holes lens, but the printing ink will cause the lack of transmittance.

Solutions

- This was the first 3D interactive design in PC industry, our unique technique was acknowledged by Israel Intel.

- Percisely controled the transmittance of 3D interactive three holes lens by using a special ink which could slightly reduce transmittance rate and meet customers' needs.

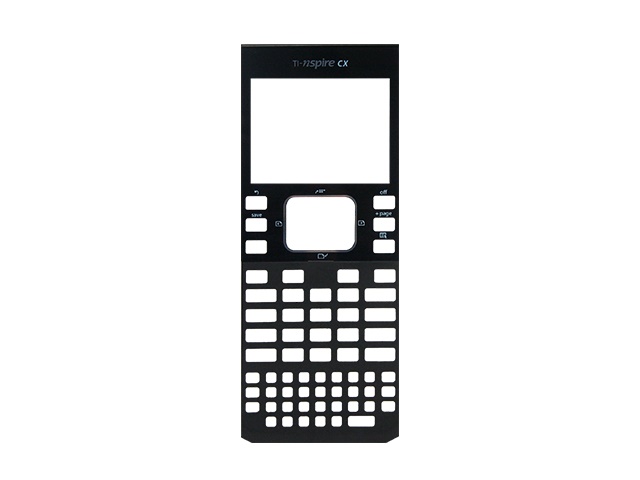

Success Stories: XPLORE Industrial Tablet S.B.C. Functional Optical Texture Frame

Requirements

- Customer required producing a product with outstanding appearance. The requirement of industrial specification and quality were rigurious.

Solutions

- We fulfilled customer's concept which attached the keyboard on the tablet by magnet and manually imbedded iron plate into Bezel Mylar, and also to achieve the high requirement of industrial specification.

- Used molding and jig laminating to achieve the requirement of adhesive avoiding at lamp aperture and interior casing. Produced in horseshoe-shaped, to achieve the reliability test and the balance of design.

Success Stories: Sony PS Vita Back Decoration Plate

Requirements

- The original protective film on the decoration plate needed tweezers to gripped the edge and tore it off with hand which contained more processes.

Solutions

- Added double indentations at the edge to make it slightly tilted, which was easier for customer to tear off the protective film and saved one process during the production.

- The product was colorful and stereoscopic. It was perfectly matched with the touch pads at the back which made the product become eye-catching.

- Back of the product was printed with scrobiculate adhesive, which could release air from the gaps while pasting, and increase the yield rate.

Success Stories: GARMIN Dummy Screen

Requirements

- At first, Cymmetrik only provided dummy screen to paste on the product glass, but the demos were consumable items. In order to reduce customer's cost, Cymmetrik suggested customer to combine the screen and design of glass frame. Negative printed at the front and laminated the bottom part of PC or PMMA, combined with punching and CNC process to achieve the simulation of real screen and depth of field.

Solutions

- Stimulated the frame of glass. Used the K plate of glass frame and screen picture, to make the glass frame contrast with the black screen. User-interface was clear at a glance.

- Improved the old process of dummy screen label, to meet customer's need on enclosure thickness. Using PC/PMMA with different thickness to provide customized solutions.

Success Stories: Huawei Smartphone Back Cover

Requirements

- Product logo required mirror effect. The original design adopted PVD plating process; however, the process was complicated, high cost and not eco-friendly.

Solutions

- We suggested customer using printing process to achieve mirror effect, which was relatively eco-friendly, simple and cost saving.

- The treatment of CD pattern and checkered design brought a strong visual impact, which presented the special glossy texture on product, successfully grab consumers' attention.

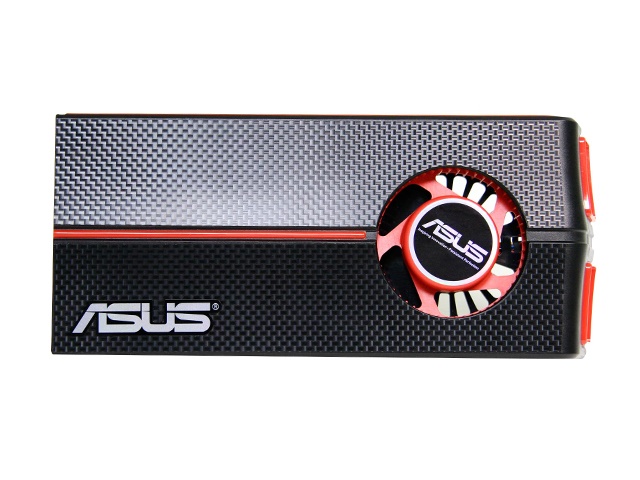

Success Stories: CAT Mobilephone Back Cover

Requirements

- Invoved in customer's initial development and promoted our design. Shortened the product development period, customer launched and started production ahead of schedule.

Solutions

- Product was designed by us, accepted by customer and launched to worldwide.

- The carbon pattern on the surface was the combination of AG logo and highlight insulation silver with pattern, to create the glittering effect, achieve customer's need.

Success Stories: Silicon Power Touch 851 USB Flash Drive Overlay

Requirements

- Product required eye-catching and impressive appearance to show the exquisite texture.

Solutions

- The classic checkered design will shine like a star with the light refraction from different angles.

- Choose gold and silver as the substrate color and combine with sputtering effect and optical treatment printing applications to show its luxury and elegant aura.