Features

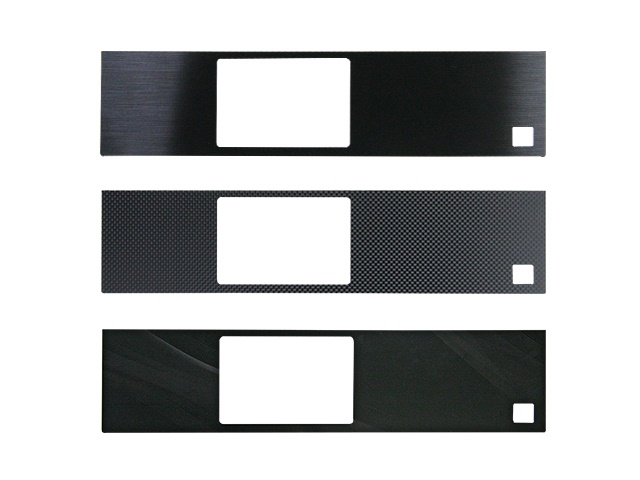

- 3D tactile feedback

- Metal texture

- Decoration before 3D forming

- Maintain color: overcome color fading problem after anodic process

- Texture can be 100% used to simulate a surface

- Trim mending process: ensure quality after edges cutting

- Rigorous product regulatory testing: temperature and humidity test, hot and cold impact test, salt spray test, abrasion resistance test, stain resistance test, chemical resistance test, etc.

Benefits

- Economical process: short production cycle, high productivity

- More eco-friendly than anodic process

- Grab consumers' attention

- Create product differentiation

- Meet customers' specific requirements

Applications

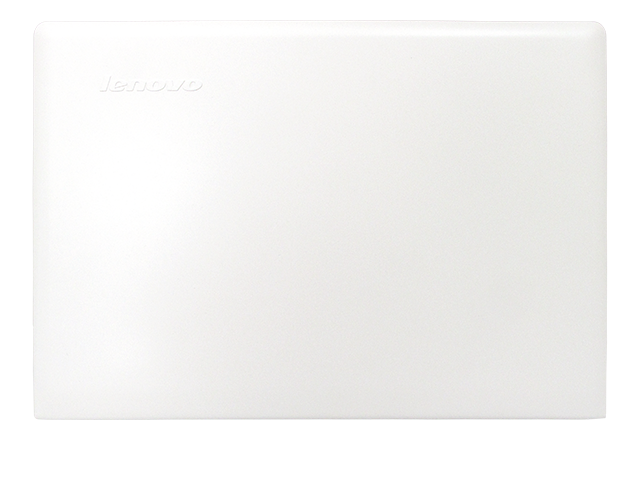

Success Stories: Lenovo I2000IRIS Back Cover

Requirements

- Customer used four bright colors on the product and all in metallic material. Using anodic process to present the texture treatment, but the effect was not obvious on the white version. If using spraying then the product would loose the feeling of light and thin and the meaning of using metallic material. Therefore, we suggested customer to used MPD process to print the metallic material into white and added AG effect to present matte tactile feedback and fulfill the whole series design concept and emphasize the eco-friendliness of the product.

Solutions

- Using MPD process to print the metallic material into white and match with pearl powder to create AG effect, perfectly present modest luxury style.

- The included angles at both side altered to arcs, which can give people tender impression and avoide ink dehiscing at the included angles.