Features

- Simultaneous multi-layer lamination

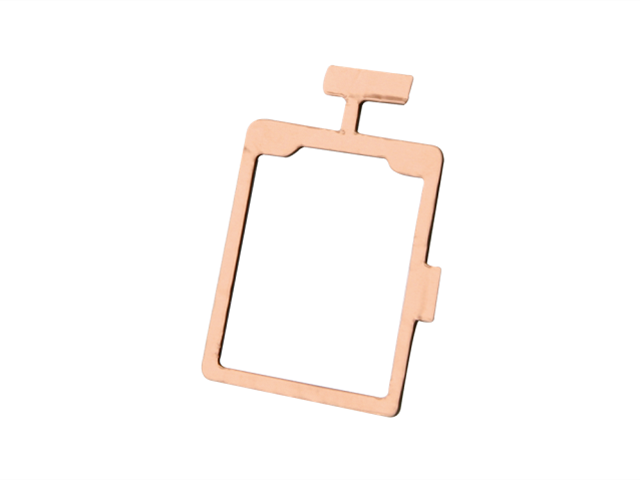

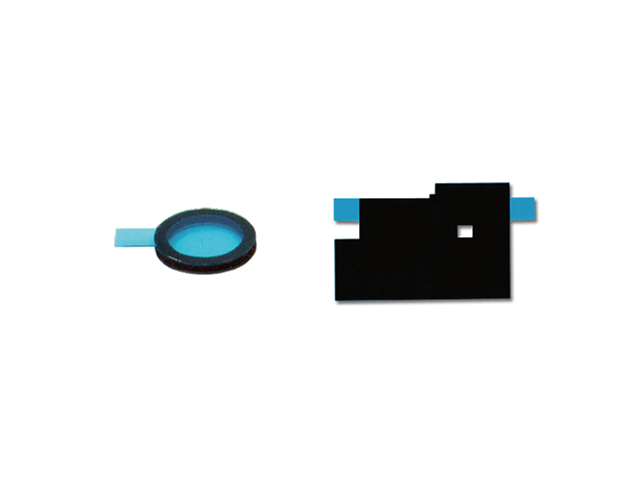

- Laminates different materials, such as double-sided tapes, foams, unsupportive films, insulation materials, functional film, foils, etc.

- Complex converting capability: produces frame-cutting, punching, embossing, and waste removal with respect to different layers and laminates to final products

- High precision

Benefits

- Meet customers' needs

- Custom production: cuts and laminates different layers of material with different shapes based on customer needs

- Diversified product applications: Can be used as shields against EMI/RFI, thermal management, insulation, water resistance, buffers, gaskets, acoustical design, bonding, protection or coating. It is best suited for decorative trim parts and components of mobile phones, consumer electronic devices, car electronics or medical equipment.

- High production efficiency